Introduction

Hastelloy pipe fittings have become an essential component in industries that require exceptional resistance to corrosion, high pressure, and extreme temperatures. When compared to traditional stainless steel, Hastelloy offers several unique advantages, particularly in harsh environments like oil and gas, chemical processing, and aerospace. In this blog, we’ll explore the differences between Hastelloy and stainless steel pipe fittings, and why Hastelloy is often the material of choice for corrosion-resistant and high-pressure systems.

What Are Hastelloy Pipe Fittings?

Hastelloy is a trademarked name for a series of corrosion-resistant metal alloys primarily composed of nickel, with varying amounts of molybdenum, chromium, and iron. These alloys are designed to withstand extreme environments, particularly those involving corrosive substances. Hastelloy pipe fittings, including Hastelloy C22 flanges and Hastelloy C276 pipe fittings, are often used in industries like chemical processing, pharmaceuticals, oil and gas, and marine applications.

Hastelloy’s unique composition makes it ideal for applications that involve exposure to aggressive chemicals, high temperatures, and pressure, where traditional materials like stainless steel would fail.

Hastelloy Pipe Fittings vs Stainless Steel

Both Hastelloy and stainless steel are used in a wide variety of industries, but each material has its own set of advantages depending on the application. Let’s compare them in terms of their key properties and suitability for different systems.

1. Corrosion Resistance

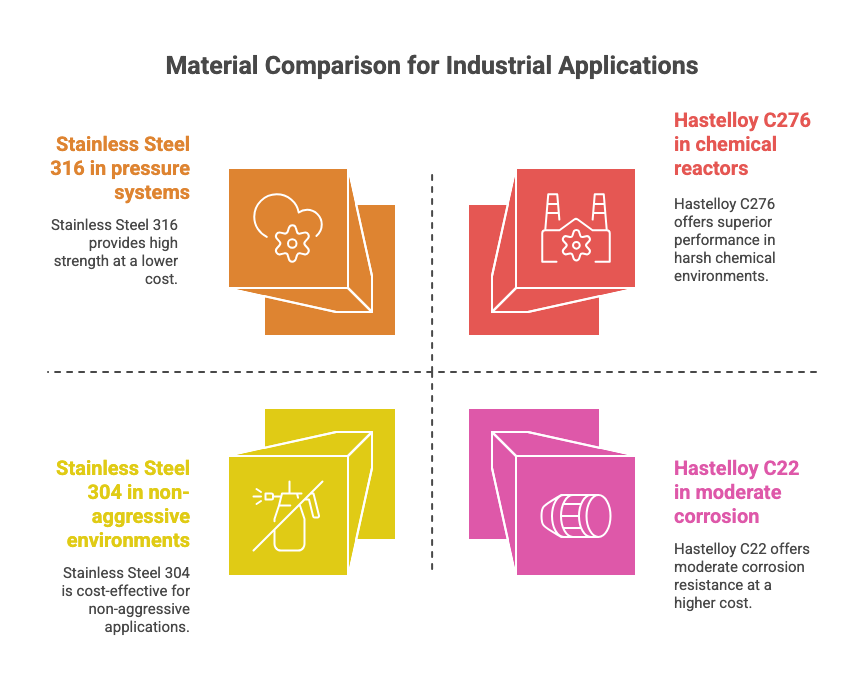

- Hastelloy: One of the standout features of Hastelloy alloys, particularly Hastelloy C22 and Hastelloy C276, is their exceptional resistance to corrosion in a wide range of environments. They offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in environments that contain chlorine, sulfuric acid, and other aggressive substances. Hastelloy C276 is particularly effective in highly corrosive environments, including hydrochloric acid and other harsh chemicals.

- Stainless Steel: While stainless steel, particularly 304 and 316, is known for its corrosion resistance, it is more susceptible to pitting and crevice corrosion when exposed to highly acidic or chloride-rich environments. Stainless steel may perform well in non-aggressive conditions, but it does not compare to Hastelloy’s corrosion resistance in more aggressive chemical environments.

2. High-Temperature Resistance

- Hastelloy: Hastelloy alloys maintain their strength and resistance to oxidation even at high temperatures, often exceeding 1000°F (537°C). They are well-suited for extreme environments where high heat is a factor, such as in chemical reactors, furnaces, or high-temperature fluid systems.

- Stainless Steel: Stainless steel also has good high-temperature properties but is more prone to weakening at elevated temperatures compared to Hastelloy. The properties of stainless steel, especially 304 and 316, begin to degrade at temperatures above 800°F (427°C), making them less suitable for very high-temperature applications.

3. Strength and Durability

- Hastelloy: While Hastelloy alloys are known for their outstanding corrosion resistance, they also offer high strength and durability, making them ideal for high-pressure applications. Hastelloy C276, for example, is frequently used in high-pressure environments in the chemical processing industry due to its excellent mechanical properties and ability to withstand intense stresses.

- Stainless Steel: Stainless steel is also strong and durable, but it does not always offer the same level of strength under high-pressure conditions as Hastelloy. However, 316 stainless steel offers high strength and is commonly used in pressure systems, although it may fail in environments with high chloride content.

4. Cost

- Hastelloy: Due to its superior properties, Hastelloy is significantly more expensive than stainless steel. The high cost can be a major consideration when selecting materials for large-scale applications. However, its longer lifespan and reduced maintenance needs in harsh environments may justify the initial investment.

- Stainless Steel: Stainless steel is more cost-effective than Hastelloy and can still provide good performance in many environments. It is widely available, making it a more budget-friendly option for many applications.

Key Applications of Hastelloy Pipe Fittings

Given its superior properties, Hastelloy is commonly used in the following industries:

- Oil and Gas: In the oil and gas industry, Hastelloy pipe fittings are used to transport fluids and gases that can cause severe corrosion in other metals, especially in offshore oil drilling platforms and subsea pipelines.

- Chemical Processing: Hastelloy is used in chemical reactors, heat exchangers, and pipelines where highly corrosive substances, such as acids and chlorides, are involved.

- Aerospace: Hastelloy alloys are used in aerospace components due to their high strength, resistance to oxidation, and ability to withstand high temperatures.

- Pharmaceuticals: In pharmaceutical applications, Hastelloy is used in processing equipment where resistance to contamination and corrosion is crucial.

Conclusion

When choosing between Hastelloy and stainless steel pipe fittings, it ultimately depends on the specific requirements of the application. Hastelloy excels in extreme environments, offering unparalleled corrosion resistance and high-temperature strength, making it the material of choice for chemical, oil and gas, and marine applications that involve aggressive chemicals, high pressure, and heat.

On the other hand, stainless steel remains a cost-effective and reliable option for many industrial applications, especially when the environment isn’t as aggressive, and when budget is a significant factor.

For industries demanding exceptional resistance to corrosion, extreme temperatures, and high pressures, Hastelloy fittings, such as Hastelloy C22 flanges and Hastelloy C276 pipe fittings, are often the best choice.

FAQs

Hastelloy is a family of corrosion-resistant metal alloys primarily composed of nickel, with added amounts of molybdenum, chromium, and iron, making it ideal for extreme environments.

Yes, Hastelloy is more expensive than stainless steel due to its superior properties and performance in extreme environments.

Hastelloy C276 pipe fittings offer exceptional resistance to corrosion in a wide range of harsh chemicals and high-temperature environments, making them ideal for industries like chemical processing and oil and gas.

Hastelloy offers significantly better corrosion resistance than stainless steel, especially in harsh environments containing acids, chlorides, and other aggressive chemicals.