Introduction

Titanium plates are an indispensable material in many industries due to their impressive strength, low density, and excellent resistance to corrosion. From the aerospace sector to medical applications and marine environments, titanium’s remarkable properties make it the go-to metal for critical components and structures. In this blog, we will explore what titanium plates are, their uses, and why they’re essential in aerospace, medical, and marine industries.

What is Titanium?

Titanium is a lightweight, durable, and corrosion-resistant metal known for its high strength-to-weight ratio. It has a silver-grey colour and is most commonly found in the form of titanium dioxide (TiO2) in nature. Titanium is highly resistant to corrosion and oxidation, even in harsh environments such as seawater and acidic conditions, which is why it is so valued in a wide range of industries.

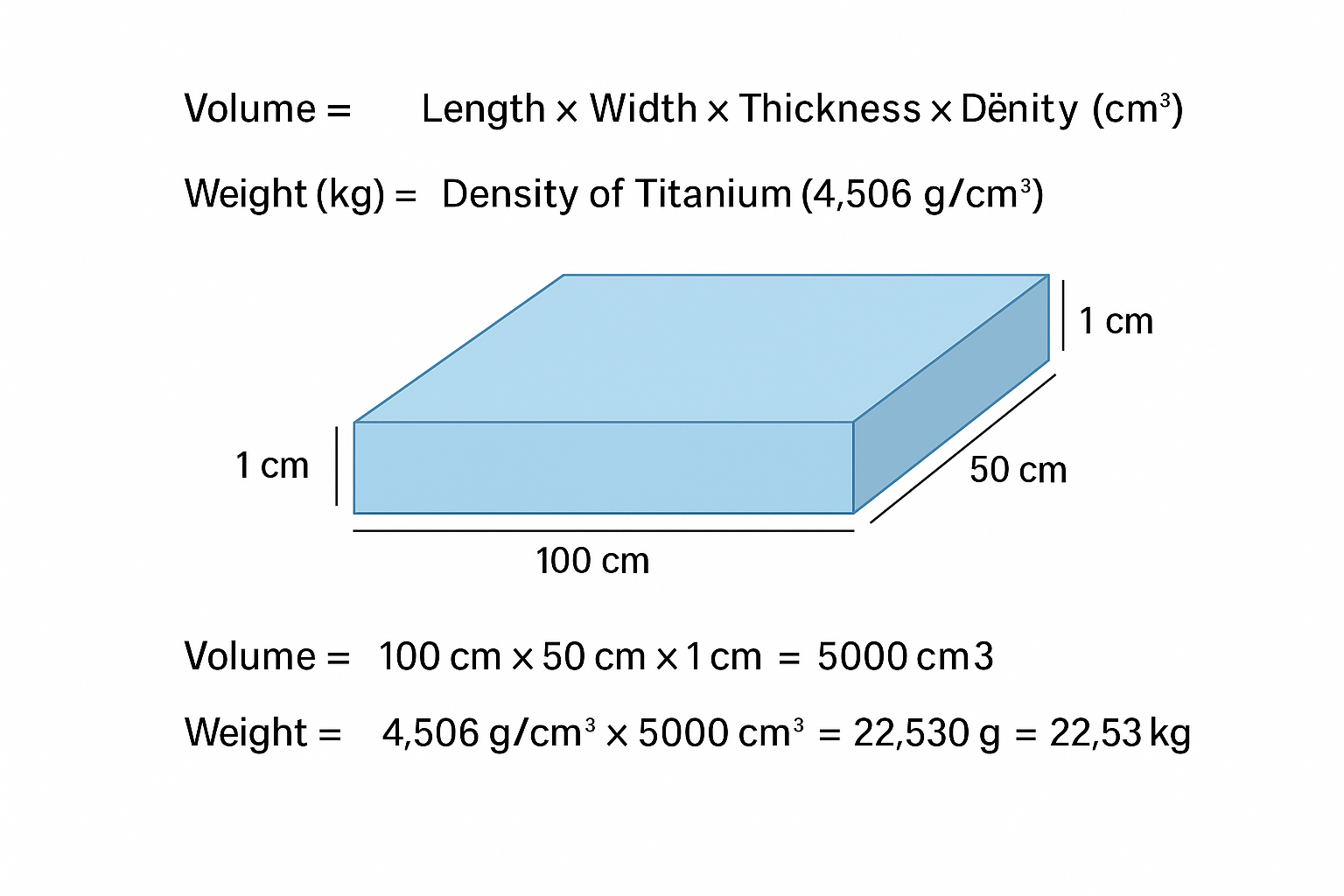

Titanium Plate Weight Calculator

To calculate the weight of a titanium plate, we use the formula for the volume of a rectangular plate:

Why Titanium Plates Are Essential in Aerospace

Titanium is widely used in the aerospace industry due to its combination of strength, lightness, and resistance to extreme temperatures. Titanium plate is used to manufacture critical components such as:

- Aircraft Wings: Titanium plates are used in the manufacture of aircraft wings due to their excellent strength-to-weight ratio.

- Engine Components: Many engine parts, including turbine blades and compressor blades, are made from titanium alloys.

- Landing Gear: Titanium is used in the manufacturing of landing gear components due to its strength and durability under high stress.

- Titanium’s ability to withstand extreme temperatures and resist corrosion from both saltwater and jet fuel makes it the perfect material for these aerospace applications.

Titanium Plates in the Medical Industry

The medical industry also benefits from the use of titanium plates, which are particularly valued for their biocompatibility and the ability to be accepted by the human body without causing adverse reactions. Some common applications include:

- Medical Implants: A Titanium plate is used in orthopaedic surgeries to repair bones, including in spinal fusion surgeries, joint replacements, and dental implants.

- Surgical Tools: Titanium is used to manufacture surgical instruments like forceps, scalpels, and clamps because of its strength, resistance to corrosion, and non-reactivity with bodily fluids.

- Prosthetics: Titanium is used in prosthetic limbs and implants, offering both strength and lightweight properties for comfort and functionality.

Titanium Plates in Marine Applications

In the marine industry, titanium plate is favoured for their outstanding corrosion resistance, particularly in saltwater environments. Applications include:

- Submarine Hulls: Titanium plates are used to manufacture the hulls of submarines, providing resistance to corrosion and the high pressures found at great depths.

- Marine Equipment: Many parts of marine vessels, such as propellers, heat exchangers, and pumps, are made from titanium due to its resistance to saltwater corrosion.

- Offshore Oil and Gas Platforms: Titanium plates are used in equipment that operates in saltwater environments, where traditional metals would quickly degrade.

Conclusion

Titanium plates play a crucial role in a wide variety of industries, including aerospace, medical, and marine. Their unique properties—lightweight, durable, and resistant to corrosion—make them an indispensable material in the production of critical components. Whether it’s for aircraft wings, medical implants, or marine equipment, titanium continues to outperform other metals, offering a reliable and long-lasting solution for the most demanding applications.

FAQs

Titanium plates are made of pure titanium or titanium alloys, which typically contain elements like aluminium, vanadium, and molybdenum to enhance the material’s strength, durability, and resistance to corrosion.

Titanium plates are preferred in aerospace due to their combination of lightweight and high strength. They are resistant to high temperatures and corrosion, making them ideal for critical components like aircraft wings and engine parts.

Titanium plates are used in medical implants, orthopaedic surgeries, dental implants, and surgical tools. Their biocompatibility makes them ideal for use in the human body, as they are non-toxic and do not cause adverse reactions.

To calculate the weight of a titanium plate, multiply its volume (length × width × thickness) by the density of titanium (4.506 g/cm³) to obtain the weight in grams, and then convert to kilograms.