What Is Carbon Steel Wire Used For in Modern Manufacturing?

Ever wonder why the foundation of contemporary manufacturing sectors is robust, long-lasting, and economical? Carbon steel wire is one of the most important but underappreciated parts. Carbon steel wire and its variations, such as precise carbon steel coils and strips, are essential for any industry, including electronics, construction, and automotive.

This article will discuss the applications of carbon steel wire, how it fits into contemporary production, and why it’s more important than ever to source from a reputable carbon steel strip manufacturer.

What Is Carbon Steel Wire?

Carbon steel wire is created by drawing high- or low-carbon steel through a die to create a thin, flexible strand. It is perfect for industrial and structural applications because of its carbon content, which provides a special blend of strength, ductility, and cost.

The wire may be coated, annealed, tempered, or galvanised, depending on the use. Because of its adaptability, it continues to be a mainstay in many different industries.

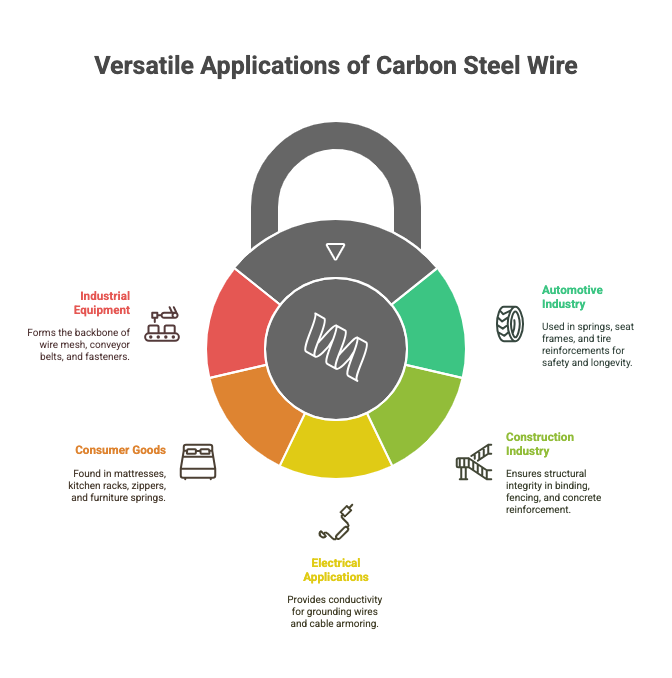

Top Uses of Carbon Steel Wire in Modern Manufacturing

1. Automobile Parts:

Carbon steel wire finds extensive application in the production of tire reinforcements, seat frames and springs. It gives automobile parts longevity and safety because of its great tensile strength and resilience.

2. The Construction Sector:

Carbon steel wire guarantees structural stability when it is used for binding, fencing, and reinforcing concrete constructions. It is common practice to cut and shape precision carbon steel strips into necessary reinforcements and fasteners for construction.

3. Uses of Electrical Equipment:

Because of its conductivity, the wire is a sensible option for cable armouring and grounding wires. Carbon steel can perform better than other metals in high-temperature settings in terms of strength and dependability.

4. Consumer Products:

Commonplace items including furniture springs, kitchen racks, mattresses, and zippers contain carbon steel wire. Because of its versatility, producers can produce strong, lightweight products in large quantities.

5. Equipment for Industry:

Carbon steel wire serves as the foundation for numerous industrial equipment and support systems, ranging from cable trays and fasteners to wire mesh and conveyor belts.

Why Precision Carbon Steel Strip & Coils Matter

If you think carbon steel wire is impressive, meet its close relatives—precision carbon steel strips and carbon steel coils. These are flat-rolled products that provide:

- Consistent thickness for critical applications

- Superior flatness and surface finish

- Excellent machinability and formability

Manufacturers rely on advanced carbon steel strips for tasks where accuracy and consistency are non-negotiable—like electronic casings, surgical tools, and precision cutting components.

How to Choose the Right Carbon Steel Strip Manufacturer

When sourcing carbon steel wire or strip materials, don’t just go for the cheapest option. A reputable carbon steel strip manufacturer ensures:

- Certified materials that meet international standards

- Strict quality control during rolling and annealing

- Custom sizes, finishes, and packaging based on your industry needs

Choosing a trusted supplier like Stellanox Steel can make all the difference in your production line’s efficiency and product durability.

People Also Ask

Is carbon steel wire better than stainless steel wire?

It depends on your application. Carbon steel wire offers better strength and is more cost-effective for structural and load-bearing uses, while stainless steel provides corrosion resistance in harsh environments.

Can carbon steel wire be welded?

Yes, most types of carbon steel wire can be welded, brazed, or soldered, making it a flexible choice for assembly and repairs.

What thicknesses are available in carbon steel strips?

Precision carbon steel strips are available in thicknesses ranging from 0.1 mm to 3 mm, depending on the application and manufacturing capability.

What’s the difference between carbon steel coil and strip?

Carbon steel coil refers to the rolled steel as a whole, while carbon steel strip is the flat product that results when the coil is slit into narrower widths.

Conclusion

More than merely a component, carbon steel wire is a high-performance, adaptable material that serves a variety of manufacturing industries. Its strength, versatility, and affordability make aluminium essential for everything from electronic devices to automobile frames.

Integrating precision carbon steel strips and buying from a reputable carbon steel strip manufacturer such as Stellanox Steel guarantees quality, performance, and adherence to contemporary requirements for manufacturers seeking to stay ahead of the competition.

FAQs

Its strength-to-cost ratio, versatility, and wide range of applications make it a preferred material for both large-scale and precision manufacturing.

It’s used in automotive body parts, electronic components, cutting tools, and even medical instruments, thanks to its precision and machinability.

Yes, leading manufacturers like Stellanox Steel offer custom widths, thicknesses, and finishes for different industry requirements.

Absolutely. Its uniform surface and consistency make it ideal for laser, plasma, and waterjet cutting in advanced manufacturing.