Introduction

Duplex steel pipes have become a critical component in industries that demand high strength, corrosion resistance, and durability. Their unique composition combining both austenitic and ferritic steel properties—makes duplex steel pipes highly effective in tough environments, such as chemical processing, oil and gas exploration, and marine applications. In this blog, we will explore what duplex steel pipes are, the different types, and why they are essential in these high-demand industries.

What Are Duplex Steel Pipes?

Duplex steel pipes are made from an alloy that contains both austenitic and ferritic structures, which combine to offer a range of beneficial properties. The key features of duplex steel include:

- Strength: Duplex steel is stronger than most austenitic and ferritic steels, which makes it ideal for handling high-pressure and high-stress environments.

- Corrosion Resistance: Duplex steel provides excellent resistance to various forms of corrosion, including pitting, crevice, and stress corrosion cracking, thanks to its high chromium and molybdenum content.

- Toughness: With improved mechanical properties, duplex steel offers higher resistance to mechanical stresses compared to traditional steels.

Duplex Steel Pipe Grades

There are several grades of duplex steel used in manufacturing duplex steel pipes, the most common being:

- 2205: This is the most widely used duplex grade and is ideal for environments that require resistance to corrosion, such as in the marine and chemical processing industries.

- 2507: Known as super duplex stainless steel, it offers even better corrosion resistance than 2205, making it suitable for more aggressive environments such as offshore oil platforms and desalination plants.

Each grade offers different mechanical properties and corrosion resistance, allowing it to be selected based on the application’s specific requirements.

Types of Steel Pipes

There are several types of steel pipes, each serving different purposes depending on the application. The main types of steel pipes include:

- Seamless Steel Pipes: These pipes are manufactured without welding and are stronger, as they don’t have seams that can weaken the pipe. They are ideal for high-pressure applications.

- Welded Steel Pipes: These pipes are made by welding steel plates together, making them a cost-effective option for lower-pressure applications.

- Spiral Welded Pipes: Made by spirally welding steel strips, these pipes are used in large-diameter applications and are commonly used in transportation pipelines.

- Duplex Steel Pipes: These pipes combine the properties of both austenitic and ferritic steel, offering superior resistance to corrosion, high strength, and good toughness.

Why Duplex Steel Pipes Are Essential?

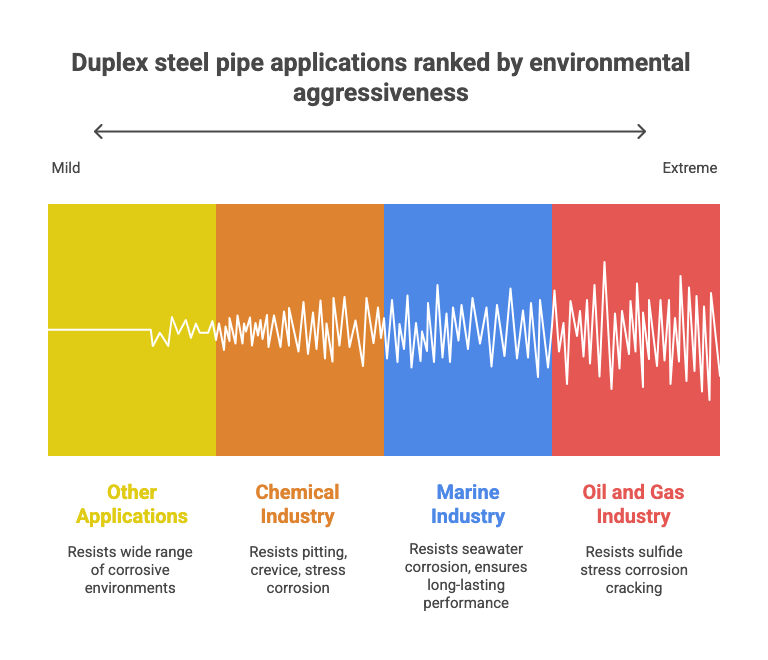

1. Chemical Industry

In chemical processing, the environment is often aggressive, with high exposure to acids, salts, and chemicals that can corrode materials. Duplex steel pipes are essential in this industry for the following reasons:

- Corrosion Resistance: Duplex steel pipes resist pitting, crevice corrosion, and stress corrosion cracking, which makes them ideal for transporting corrosive chemicals.

- Durability: The high strength and toughness of duplex steel pipes ensure that they can withstand the harsh and high-pressure environments common in chemical manufacturing.

- Long Lifespan: Due to their resistance to corrosion, duplex steel pipes are more durable than other steel types, reducing maintenance and replacement costs.

2. Oil and Gas Industry

The oil and gas industry often deals with high-pressure pipelines and aggressive environments. Duplex steel pipes offer the following advantages in these applications:

- Resistance to Sulfide Stress Corrosion Cracking: Duplex steel pipes are resistant to sulfide stress corrosion cracking (SSCC), a common issue in oil and gas drilling and production.

- High Strength: Duplex steel’s high strength makes it suitable for deepwater pipelines and high-pressure systems used in offshore drilling.

- Impact Resistance: Duplex steel can withstand the mechanical stresses often encountered in offshore platforms and pipelines, ensuring reliable operation under tough conditions.

3. Marine Industry

The marine industry requires materials that can withstand the corrosive effects of saltwater. Duplex steel pipes are vital in marine applications due to their:

- Excellent Corrosion Resistance: Duplex steel pipes offer exceptional resistance to seawater corrosion, ensuring long-lasting performance in marine environments.

- Strength: Duplex steel’s strength allows for its use in demanding offshore applications, such as in the construction of ships, platforms, and other marine structures.

- Low Maintenance: The durability and corrosion resistance of duplex steel reduce the frequency of maintenance, saving both time and cost in marine operations.

4. Other Applications

Duplex steel pipes are also used in other applications such as heat exchangers, pressure vessels, desalination plants, and power plants due to their high strength and resistance to a wide range of corrosive environments.

Conclusion

Duplex steel pipes are an essential component in industries where strength, corrosion resistance, and durability are critical. Their unique combination of austenitic and ferritic properties makes them ideal for applications in the chemical, oil, gas, and marine industries. Whether it’s for handling aggressive chemicals, withstanding high-pressure environments, or ensuring reliable performance in harsh marine conditions, duplex steel pipes offer a reliable and long-lasting solution for some of the most demanding applications.

FAQs

Titanium plates are made of pure titanium or titanium alloys, which typically contain elements like aluminium, vanadium, and molybdenum to enhance the material’s strength, durability, and resistance to corrosion.

Titanium plates are preferred in aerospace due to their combination of lightweight and high strength. They are resistant to high temperatures and corrosion, making them ideal for critical components like aircraft wings and engine parts.

Titanium plates are used in medical implants, orthopaedic surgeries, dental implants, and surgical tools. Their biocompatibility makes them ideal for use in the human body, as they are non-toxic and do not cause adverse reactions.

To calculate the weight of a titanium plate, multiply its volume (length × width × thickness) by the density of titanium (4.506 g/cm³) to obtain the weight in grams, and then convert to kilograms.