Introduction

Titanium rods have earned their reputation in industries requiring strength, lightness, and resistance to corrosion. While steel has traditionally been the go-to material for various applications, titanium rods have shown superior performance in high-demand environments. From aerospace to medical fields, titanium rods offer exceptional properties that make them an excellent alternative. In this blog, we’ll explore what titanium rods are, their uses, and why they outperform steel in specific applications.

What is Titanium Metal?

Titanium is a chemical element known for its remarkable strength-to-weight ratio and exceptional corrosion resistance. It is as strong as steel but much lighter, making it ideal for applications where weight is a concern, such as in the aerospace and automotive industries. Titanium is naturally resistant to corrosion from sea water, chlorine, and most acids, making it a top choice for challenging environments.

Titanium exists in various grades, each with specific alloy compositions designed to provide specific strengths and capabilities. Grade 5 (Ti-6Al-4V), one of the most commonly used grades, is especially renowned for its excellent strength and corrosion resistance.

What are Titanium Rods?

Titanium rods are long, cylindrical pieces of titanium metal, often used in industries where high strength and resistance to harsh environments are crucial. These rods are fabricated using high-purity titanium and are available in various sizes, lengths, and diameters. They are widely used in aerospace, medical implants, chemical processing, and sporting equipment, to name a few.

Titanium Rods vs Steel: Why Titanium Outperforms Steel

While both titanium and steel are strong metals, titanium rods offer some significant advantages in specific high-performance, corrosion-resistant applications. Here’s why titanium outperforms steel:

- Corrosion Resistance: Titanium is extremely resistant to corrosion, including rust and pitting, even in harsh environments like seawater, chlorine, and acidic conditions. Steel, on the other hand, can corrode over time if not properly protected.

- Strength-to-Weight Ratio: Titanium has a much lower density than steel (approximately 45% lighter), meaning titanium rods provide the same strength as steel but at a fraction of the weight. This makes titanium ideal for industries like aerospace, where reducing weight is critical.

- Temperature Resistance: Titanium rods can withstand higher temperatures than steel without losing their mechanical properties. This makes them ideal for high-heat applications, such as in jet engines and industrial equipment.

- Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and will not cause adverse reactions in the human body. This is why it’s often used in medical implants, prosthetics, and surgical tools. Steel, while used in some medical devices, is not as compatible as titanium.

Uses of Titanium Rods

Titanium rods are utilized in a wide variety of industries due to their impressive properties. Here are some common uses:

- Aerospace: Titanium rods are used extensively in the aerospace industry to manufacture parts that require both strength and low weight, such as landing gear, turbine blades, and structural components.

- Medical Implants: Due to their biocompatibility, titanium rods are commonly used in medical applications for prosthetics, joint replacements, and dental implants.

- Chemical Processing: The resistance of titanium rods to corrosion makes them ideal for equipment used in chemical processing, where exposure to harsh chemicals is common.

- Sports Equipment: Titanium is used in high-performance sporting equipment such as golf clubs, bicycle frames, and archery bows, where strength and weight reduction are essential.

- Marine Applications: Titanium rods are ideal for use in marine environments, including boat parts, underwater equipment, and naval structures, due to their resistance to saltwater corrosion.

Why Super Duplex Stainless Steel is Ideal for Corrosion Resistance

Super duplex stainless steel’s high corrosion resistance makes it the go-to choice for industries dealing with aggressive environments. Some of the primary reasons include:

- Chloride Resistance: Its high molybdenum and nitrogen content gives it exceptional resistance to chloride-induced stress corrosion cracking, which is commonly seen in marine environments.

- Pitting Resistance: The increased chromium content ensures that the alloy resists pitting corrosion, which occurs when localised areas of the material are exposed to aggressive chemicals or salts.

- Long-Term Durability: Super duplex stainless steel is built to last in harsh conditions, offering long-term reliability and reducing the need for frequent maintenance or replacements.

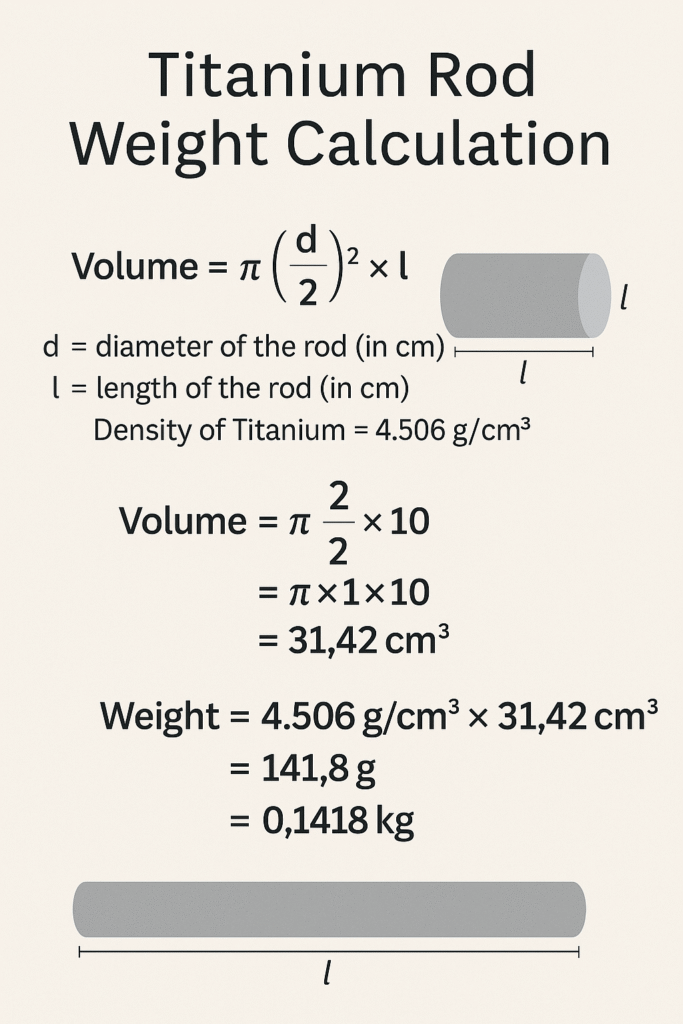

Titanium Rod Weight Calculator

Variables:

- d = diameter of the rod (in cm)

- l = length of the rod (in cm)

- Density of Titanium = 4.506 g/cm³

For example, if you have a titanium rod with a diameter of 2 cm and a length of 10 cm:

Conclusion

Titanium rods are an invaluable material in industries that demand high strength, resistance to corrosion, and durability under extreme conditions. With superior properties like a high strength-to-weight ratio and biocompatibility, titanium rods have become the material of choice for aerospace, medical, marine, and chemical industries. While steel still holds its ground in many areas, titanium continues to outperform it in specialized applications that require high performance in harsh environments.

FAQs

Titanium rods are made of high-purity titanium metal, which is alloyed with other elements like aluminum, vanadium, and molybdenum to enhance their properties, including strength and corrosion resistance.

Titanium rods are approximately 45% lighter than steel rods, making them ideal for applications where reducing weight is crucial without sacrificing strength.

Yes, titanium rods are widely used in medical implants due to their biocompatibility, which ensures that they are non-toxic and safe for use in the human body.

The weight of a titanium rod can be calculated using the formula: Weight = Density of Titanium × Volume of the rod. The volume of the rod is calculated using its diameter and length.